The combined rice mill plant is a complete set of rice milling equipment. It is composed of several single machines. It uses mechanical force generated by mechanical equipment to peel and whiten brown rice.

We have a 15-ton rice milling plant, a 20-ton rice milling plant, a 25-ton rice milling plant, a 30-ton rice milling plant, a 40-ton rice milling plant, and so on. The main thing to share with you here is the 15-ton rice mill plant.

Application of automatic rice mill plant

The Rice milling plant is mainly used to turn brown rice into white rice. The rice milling plant is a new type of rice processing equipment. It was improved based on a single machine.

It is suitable for individual farmers, towns, schools, and other units. Also, specialized grain processing households and small rice processing plants can apply it.

Technical parameters of rice milling machine

| Model | NZJ15 |

| Capacity | 15 tons per day |

| Raw material | Paddy rice |

| Final products | White rice |

| Power | 20.87kw |

| Size | 4 * 3.5 *4 m |

Working video of the combined rice mill plant

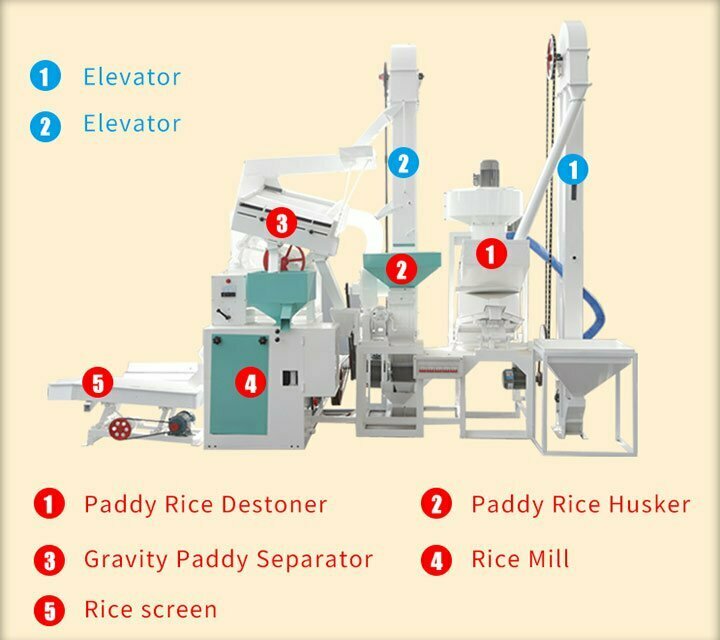

What equipment does the automatic rice milling plant include?

The whole combined rice mill plant includes a hopper, stone remover, hulling machine, gravity grading sieve, rice milling machine, and white rice grading sieve. Color sorter and sieving can as your auxiliary choice.

What are the uses of individual machines?

- The silo is used to store rice.

- The stone remover (stone destoner) is used to remove impurities such as small stones in the rice.

- The rice dehulling machine is used to remove the husk of the rice. so that becomes brown rice.

- Gravity sieving equipment can sieve rice into brown rice, the mixture of brown rice and paddy, paddy.

- The rice milling machine grinds brown rice into white rice.

- The sieving machine can further sieve the rice so that the rice is cleaner and has a uniform particle size.

This destoner can remove

the small stone, soil, dust, etc.

This machine mainly removes the rice husk,

and the shelling rate reaches 99%

This rice mill is suitable for all types of rice,

no matter if your rice is long or small, you can use this rice mill.

Structure of the automatic combined rice mill plant

This equipment adopts the form of a steel structure. Each stand-alone machine is extremely easy to disassemble and assemble. So it is convenient for users to purchase the required single machine and other equipment to form a complete set of processing equipment.

Is the automatic rice milling plant fixed?

Of course not. The combined rice mill plant mentioned above includes the most basic equipment. We can also customize the rice milling unit according to your needs. For example, polishing machines, color sorters, square screens, etc. can be chosen.

The polishing machine can make the rice whiter and brighter. The color sorter can remove moldy rice, black rice, and brown rice, so your rice quality is very high.

What is the rice milling process?

The rice is sent from the hoist to the cleaning and stone removal machine to remove impurities and stones. Then the rice is sent to the dehulling machine by hoist for dehulling. The big husker is removed from the machine by the fan, and the dehulled rice mixture is conveyed to the gravity-sieving equipment by the double hoist.

The unhulled rice is sent back to the dehulling machine by the gravity sieve duct to be dehulled again. The brown rice enters the rice mill for milling and then is collected and packaged after being whitened by the polisher.

What is the advantage of an automatic rice mill plant?

- Adopt the arrangement and combination method to make the whole rice mill plant run smoothly, with simple operation and convenient maintenance.

- The cleaning stone removal machine is an absorption-type, which has a reliable and stable stone removal effect. Also, it can reduce dust pollution during feeding and improve the operating environment.

- This equipment adopts a self-developed pulverizing system. The large rice husker and clear husker can be mixed into the crusher at the same time to be mixed and processed into a uniform powder. So that the by-products can be fully utilized and the user’s economic benefits are increased.

- This equipment can work in combination or alone, so its maintenance and transportation are more convenient

- According to the design characteristics of this equipment, it can not only carry out independent agricultural processing but also continuous processing of commercial grains. The dual purpose of one machine makes the current rice milling equipment a new generation of products.

How effective is the rice mill?

The effect of rice milling has been recognized by customers, and the efficiency of rice milling is very high. The rice rate reached 71%.

How does rice husk realize the added economic value?

The pulverizer machine can crush the rice husk, and the crushed rice husk can make feed pellets for livestock and animals. In addition, the crushed rice husk can make rods.

About packing and shipping

If you are transporting it in a combined container, we will pack it in a wooden box for you. If you have a container, we will directly pack it into the container for you.

Regarding transportation, please tell us your nearest port and we will plan the most suitable transportation route for you.

What is the price of the combined rice mill plant?

As previously highlighted, the 15-ton combined rice mill plant offers flexibility in configuration, translating to variable pricing based on the chosen specifications.

The pricing structure is contingent on the specific requirements of the customer, ensuring that you have the option to tailor the configuration according to your preferences and budget.

For a more precise and personalized quotation, we encourage you to share your specific preferences regarding the rice milling unit you desire. Providing details on your requirements will enable us to offer you an accurate and tailored quote, ensuring that you receive the most cost-effective solution for your rice milling operations.

Your satisfaction is our priority, and we look forward to assisting you in creating an optimized and efficient processing setup.

How to use the combined rice mill plant to make money?

As a workshop

- You can collect rice locally, then mill the brown rice into white rice, and finally sell the rice

- You can process rice for local farmers, and then ask them for processing fees. In this way, you will quickly earn enough for the cost of the machine.

As a distributor

You can order many combined rice mill plants from us and sell them all over the world because we are a manufacturer, so the price of the machine is relatively low.

We not only have rice milling units, but we also have individual rice mills, polishers, color sorters, packaging machines, dehullers, stone removers, hoists, etc., with high selectivity.

How to install the automatic combined rice mill plant?

The installation of the entire rice milling unit is very convenient. We will label the individual machines according to the assembly sequence, as shown in the figure, so the installation is very convenient and simple. In addition, we will provide you with installation videos and installation instructions.

Conclusion

Under the leadership of our combined rice mill plant, you are embarking on a new journey in rice processing. Our equipment is not just a symbol of efficiency and excellence but also your reliable companion on the road to success. By integrating advanced technology with intelligent design, we provide you with an all-encompassing solution, making processing easier and more efficient.

Ignite your passion for the processing industry, we offer you a comprehensive solution. Contact us now to discover more about the exciting features of our product and solutions tailored to your needs. Our team is here to provide full support, ensuring that your investment propels you to new heights. Choose us and let’s create a prosperous future together!