The 15TPD rice miller machine unit is an advanced and efficient equipment that stands out in the field of rice processing. With its outstanding production capacity and precise processing technology, it has become the top choice for rice processing.

By adopting the latest technology and equipment, this unit can efficiently process rice, thereby increasing production efficiency, reducing costs, and ensuring high-quality rice output. Its stable and reliable performance also provides users with an excellent user experience.

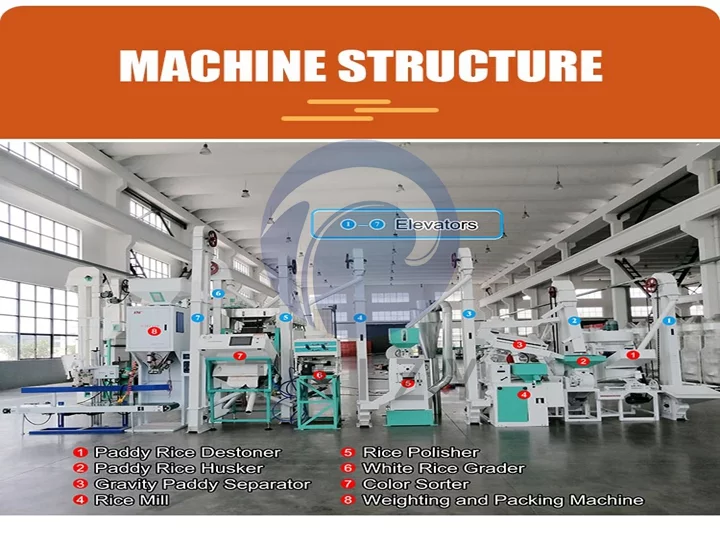

What machines are included in the 15TPD rice miller machine unit?

Our 15TPD rice milling unit is a comprehensive and efficient system that comprises a Paddy Rice Destoner, Paddy Rice Husker, Gravity Paddy Separator, Rice Mill, Rice Polisher, White Rice Grader, Color Sorter, and Weighing and Packing Machine.

This design is meticulously crafted to initiate the process by removing impurities, progressing through various refining stages, ultimately producing high-quality, pure white rice. Each component plays a crucial role within the system, working collaboratively to ensure thorough processing at every stage, resulting in a final product that meets rigorous standards.

Applications of the 15TPD rice miller machine unit

- Rice Processing Plants: The 15TPD rice miller machine unit is an ideal choice for small to medium-sized rice processing plants. It efficiently processes and mills rice, increasing production capacity and ensuring high-quality rice products.

- Farmer’s Processing: Farmers can use the 15TPD rice miller machine unit for small-scale rice processing, enhancing the value of their rice and increasing income.

- Rice Wholesalers: Rice wholesalers can invest in the 15TPD rice miller machine unit to perform primary processing of bulk rice, providing more competitive products.

- Rice Processing Cooperatives: Cooperatives can invest in and purchase the 15TPD rice miller machine unit to offer rice processing services to cooperative members, strengthening their economic capacity.

- Agricultural Cooperatives: Agricultural cooperatives can introduce the 15TPD rice miller machine unit to process paddy into rice, adding value to their products and injecting new vitality into the development of the cooperative.

The purpose of cleaning paddy

The production, harvesting, transportation, and storage of rice can result in the presence of impurities. Failing to remove these impurities beforehand can lead to significant negative consequences in the rice processing process.

For instance, if rice is mixed with various types of straw, it can lead to blockages in the conveyor pipelines and feeding machinery during production, causing disruptions in normal operations and reducing the efficiency and processing capacity of the equipment.

Additionally, there’s a risk of it being contaminated with hard impurities like sand and metal, which can damage the working equipment’s surface and potentially lead to accidents such as dust explosions.

Moreover, if the rice contains mud and dust, it can lead to airborne dust, compromising the cleanliness of the workshop environment and posing risks to human health. Any impurities left in the rice that make it into the final product can lower its purity and ultimately affect the overall quality. Therefore, the removal of impurities stands as a crucial task in the rice processing process.

How to clean the impurities in rice paddy?

The basic principle of cleaning rice grains lies in utilizing the differences in particle size, weight, and other physical characteristics between impurities and grains for separation. Despite the diverse types of impurities in rice, they generally exhibit distinctions in these properties when compared to grains.

By taking advantage of these distinctions, appropriate cleaning methods can be selected to effectively remove the impurities. Commonly used methods for impurity removal include screening and magnetic separation.

Screening method

The screening process relies on distinguishing rice grains from impurities by considering factors such as grain size (including width, thickness, and length) as well as shape. This involves choosing a sieve with specific dimensions and shape, and then using the relative movement between the material and the sieve surface to separate out impurities.

Magnetic separation method

Magnetic separation involves utilizing magnetic force to eliminate magnetic metal impurities from rice. As the material moves through the magnetic field, rice, being non-magnetic, can pass through unaffected by the magnetic field. On the other hand, metal impurities in the rice, like nails, screws, or iron filings, possess magnetic properties and readily become magnetized within the magnetic field. The opposite magnetic poles attract, causing them to separate from the rice.

Why choose to buy 15TPD rice milling machine unit from Taizy?

As your supplier for the 15TPD rice milling unit, we confidently showcase our outstanding shipping capabilities. Our meticulously designed unit features a compact structure and a modular disassembly design, optimizing space utilization during shipping to reduce transportation costs.

We offer efficient packaging solutions, with the disassembly limited to elevators and a few small components, streamlining the entire packaging process. This not only simplifies shipping but also ensures the safety of the unit during transportation.

Collaborating with reliable logistics partners, we provide flexible and efficient global logistics services. Regardless of your geographical location, we are committed to delivering the 15TPD rice milling unit to your facility on time. Our shipping team is highly professional, ensuring close communication with you throughout the process to meet your specific requirements.

Choosing us ensures top-notch shipping services, guaranteeing the safe and prompt arrival of your unit at its destination.