The 20TPD automatic combined rice milling machine is designed for processing high-quality rice and is equipped with a 60A suction-type gravity stone removing machine, color sorter, and square screen, setting it apart from other types of rice milling machines. These advanced configurations enable more efficient and precise operations in the rice processing journey.

Whether from the perspectives of stone removal, color sorting, or screening, the 20TPD automatic combined rice milling machine showcases advanced technology and outstanding performance. For users pursuing the production of high-quality rice, this automatic combined rice milling machine is an ideal investment choice.

What’s the advantage that other types of rice milling machines do not have?

- This rice milling machine is made of several parts, but each part is independent, which is easy to maintain.

- The color sorter machine has a photoelectric color selection with high precision.

- Rice destoner can clean out impurities such as stone automatically to enable the cleanliness of rice.

- The temperature of the final rice is low, and you can not find any rice husk powder in the white rice.

- Even though it boasts a very big size, there is little noise and dust.

- The rice huller part matches with gear and a 6-layer screen that can separate rice husk and brown rice effectively. The rotating grading screen can select rice with different levels, improving the quality of rice.

- The screening speed of gravity is very fast without any residue.

- The strong-wind fan can fully blow out the rice husk.

- It can work continuously for 24 hours with a capacity of 20t per day.

- Thanks to the high quality of processed rice, you pack it into a bag directly and sell it on the market.

Technical parameter of 20-ton rice mill production line

| Name | 20T/D combined rice milling machine | |

| Raw material | Paddy rice | |

| Final products | White rice | |

| Power | Rice milling machine | 26.2kw |

| Polisher machine | 16.5kw | |

| Total Power | 42.7kw | |

| Weight | 2 ton | |

| Installation area | 3500*2600*2900mm | |

| Put into | 20GP Container (6*2.34*2.34M) | |

| Material Total | Carbon steel | |

| Dimension | 5800*3500*4000mm | |

| Capacity | 900-1000kg/h 20 ton per day (24 hours) | |

| Rice milling rate | 71% | |

| Total power | 32.7Kw(without crushing machine)51.2Kw(including crushing machine) | |

| Rate of output rice | 72% (including broken rice) | |

| Rate of broken rice | 2% | |

| From rice huller machine to rice milling machine | Go straight into the milling machine | 100% (Paddy rice) |

| Back to the huller machine | 10% (Paddy rice and rice) | |

| Husk | 22% | |

| The rice came from screening machine | Grade A | 60% |

| Grade B | 10% | |

| Broken rice | 2% | |

| Notice: There are different types of rice in different countries of the world. The above figures are for reference only. | ||

The operation video of the rice miller machine

The structure and details of the rice mill machine

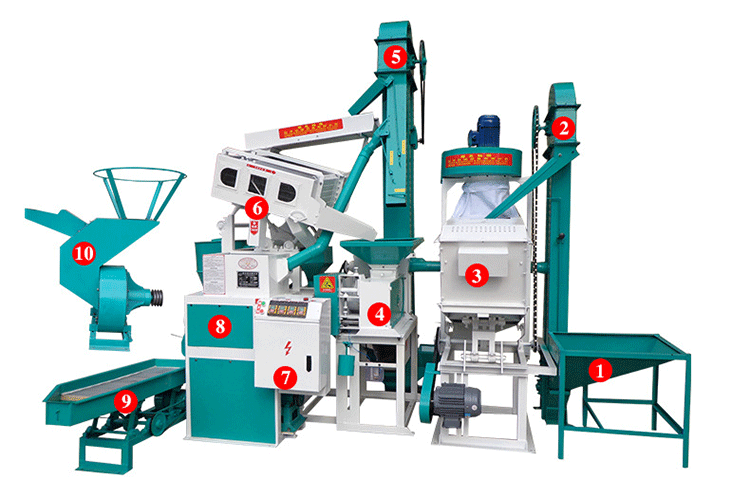

Part A: 1 2 3 4 5 6 7 8 9

Part B: 10

The main part of the combined rice milling machine

| Part A | |||

| No. | Name | Function | Set |

| 1 | Rice inlet | Feeding brown rice | 1 |

| 2 | lifter | It is single lifter, and can convey the rice into rice stone removing machine(2) | 1 |

| 3 | Rice destoner | Remove the stone and other impurities from rice | 1 |

| 4 | Rice hulling machine | Remove the rice husk. | 1 |

| 5 | lifter | Double lifter, convey rice to screening machine | 1 |

| 6 | Screening machine | Screen the impurity inside rice | 1 |

| 7 | Electric cabinet | Control the electricity | 1 |

| 8 | Rice mill machine | get the white rice | 1 |

| 9 | Square sieve | Remove the broken-rice to get the good rice | 1 |

| Part B | |||

| 10 | Crusher | Crush the rice husk | 1 |

The installation tools after you receive the machine

Due to the big size, you need several types of tools for installation. Our rice millers do not match with the following tools, so it is necessary for you to buy them locally.

Percussion Drill | Hand Type Angle Mill | 100M 380V/440V 3 phase electric line (thin) |

|  |  |

| 100M 380V/440V 3 phase electric line (Thick) | 90°pipe line (PVC 160mm, 110mm) | Straight pipe line (PVC 160mm, 110mm, 75mm) |

|  |  |

The number of each part of the combined rice milling machine

| Name | Quality (pcs) |

| A1500 Belt(Gravity Screen) | 4 |

| 1.0 Rice huller screens | 4 |

| emery roll | 1 |

| depression bar with screw | 1 |

| Polishing head | 1 |

| Conveyor head | 1 |

| B1930 Belt(Rice machine) | 3 |

| B1422 Belt(Head of the machine) | 2 |

| B940 Belt(Husk fan) | 1 |

| B1372 Belt(Oil bran fan) | 1 |

| B1499 Belt(Destoner machine) | 1 |

| A1800 Belt(Elevators) | 1 |

| 4.7m Adjustable Belt(Elevator) | 1 |

| A1041 Belt(Broken rice screen) | 1 |

| A1500 Belt(Gravity Sceen) | 2 |

| B2565 Belt(Crusher) | 3 |

| 1570 Belt | 1 |

| Gum cover of destoner | 1 |

| Gum cover of broken rice screen | 1 |

A successful case of the combined rice milling machine

In early November, a delegation of seven Nigerian mayors paid a visit to our factory, where they had the opportunity to thoroughly test the machines they were interested in. In addition to procuring various other agricultural machines from our extensive range, they decided to place an order for three sets of our 20TPD combined rice milling machines.

The delegation was particularly impressed by the exceptional cleaning efficiency of this machine. In their home country, they used to go through the hassle of re-screening the rice after milling, which consumed a significant amount of time and energy.

However, the Taizy combined rice milling machine proved to be a game-changer. Its high level of cleanliness surpassed their expectations, eliminating the need for additional screening. Consequently, they decided to pay the deposit before concluding their visit to our factory.

How to install the rice milling machine plant?

Contact us

As a supplier of the 20TPD automatic combined rice milling machine, we are dedicated to providing outstanding rice milling solutions to meet your grain processing needs. Our equipment combines advanced technology and efficient processes, ensuring the production of high-quality rice for long-term economic benefits in your business.

If you are interested in our 20TPD automatic combined rice milling machine, feel free to contact our sales team at any time. We will provide you with detailed product information and customized solutions to meet your unique production requirements. With our support, you will have an efficient and reliable rice milling equipment set to drive the flourishing growth of your business.

Contact us now and let’s create a successful future together!