The 25TPD Integrated Rice Milling Unit boasts a myriad of advantages, including its highly modernized and streamlined design that combines essential rice processing functions seamlessly.

With advanced automation, the unit ensures user-friendly operations while maintaining a remarkable balance between efficiency and product quality. Its adaptability caters to both small-scale rural and large-scale commercial production, offering users increased flexibility.

The unit stands out for its ability to significantly enhance production efficiency and elevate rice yield and quality, marking a notable advancement in the realm of agricultural technology.

Parameters of the 25TPD Integrated Rice Milling Unit

| Total Power | Capacity | Overall Size | Weight |

| 31.2kw | 25Ton/Day (1000-1200kg/h) | 3800*3500*3000mm | 2300kg |

Key Advantages of the 25TPD Integrated Rice Milling Unit

The 25T/D Integrated Rice Milling Unit holds key advantages over the 15T/D Integrated Rice Milling Unit with notable enhancements in the size and design of the destoner and an internal structural transformation to a rotary sieve.

Firstly, the increased size of the destoner signifies enhanced processing capacity, allowing for more effective removal of stone impurities from the rice, thereby improving the overall purification process.

Secondly, the shift from an inclined plane to a flat plane and the internal upgrade to a rotary sieve further elevates the efficiency and precision of the screening process, ensuring a more consistent quality of rice throughout processing.

These innovative design improvements in the 25T/D unit result in significant advancements in both processing efficiency and product quality, establishing it as a pivotal technological innovation in the field of rice milling.

Common Faults and Trouble Shooting Methods

Paddy Rice Destoner

Trouble: The efficiency of removing lightweight impurities from deflated grains is not significant, or there may be whole grains present within the lightweight impurities.

Reason: The airflow speed in the suction duct is either too low or excessively high.

Methods: Modify the airflow velocity in the suction duct to achieve an appropriate level.

Paddy Rice Husker

Trouble: The dehusking efficiency is not satisfactory.

Reason:

- The feeding size is excessive.

- The moisture content in the raw grains is excessively high.

- The pressure applied by the rubber roller is insufficient.

Methods:

- Regulate the flow to sustain the rated output.

- Implement judicious adjustments and understand the shelling process.

- Alter the rolling distance or substitute the spring if necessary.

Gravity paddy separator

Trouble: Excessive vibration or significant noise.

Reason:

- Loose anchor nuts and fasteners.

- Looseness in the draft rod lock nut.

- Inaccurate positioning of the two sets of supports or a missing bearing.

- Looseness in the outer bolt connecting the separation box and the support body. Excessive clearance between the hinge and the pin.

- The drive belt is excessively tight, and the motor shaft is not parallel to the spindle’s centerline.

- Collisions between the inlet and outlet with the material pipe.

Methods:

- Securely fasten the anchor nuts and all bolts (nails).

- Ensure it is securely tightened.

- Realign the position of each support rod and replace the worn-out bearing.

- Firmly tighten the connecting bolts and elevate the hinge column of the box to eliminate any vertical movement.

- Make adjustments to the motor base.

- Make the necessary adjustments.

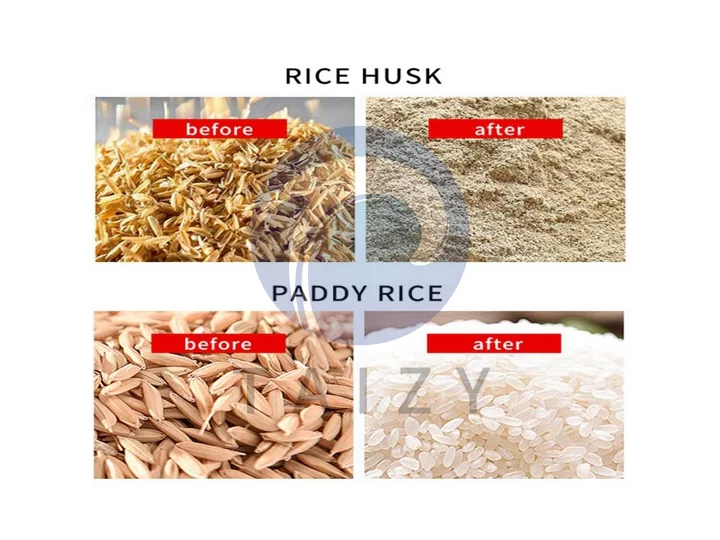

By-product of the 25TPD Integrated Rice Milling Unit

The by-product obtained from the rice milling and finishing process is a mixture of bran and rice grits, which contains not only rice bran and rice grits (fragments of endosperm smaller in size than broken rice) but also, due to factors such as broken sieve holes or improper operation, may include intact rice grains.

Rice bran holds significant economic value as it can be used to produce rice bran oil and extract products like grain cellulose and calcium phytate. It is also utilized in animal feed production. Rice grits have chemical compositions similar to whole rice and can serve as raw materials for sugar and alcohol production. Broken rice can be used to produce high-protein rice flour, beverages, alcohol, and convenient porridge.

The successful case of 25TPD Integrated Rice Milling Unit

In a remote rural area of Ghana, we witnessed the success of the 25TPD Integrated Rice Milling Unit. This unit integrates various processes including cleaning, dehusking, milling, and sieving, significantly improving the efficiency and quality of rice processing.

Farmers have seen a substantial increase in rice yield, and their product quality has gained recognition in the market, resulting in higher income. This case exemplifies the outstanding performance of the unit and underscores our profound understanding of customer needs and commitment to professional service.