Cleaning rice is a crucial step in rice processing, aimed at removing various impurities to improve the purity and quality of the finished rice and ensure smooth production.

Through the most reasonable and economical process, various impurities in rice are removed to meet the quality requirements of clean rice before milling. Simultaneously, the removed impurities must not exceed the relevant prescribed standards to ensure the safety and purity of the finished rice.

This article will explore the process of rice cleaning, its important steps, introduce the evaluation indicators of cleaning equipment effectiveness, and recommend the use of a rice destoner to optimize the cleaning process.

Rice Cleaning Process

The rice cleaning process aims to remove various impurities from rice, which is a critical step in ensuring the quality of the finished rice. The cleaning process typically includes the following steps:

Selection of Impurity Removal Equipment:

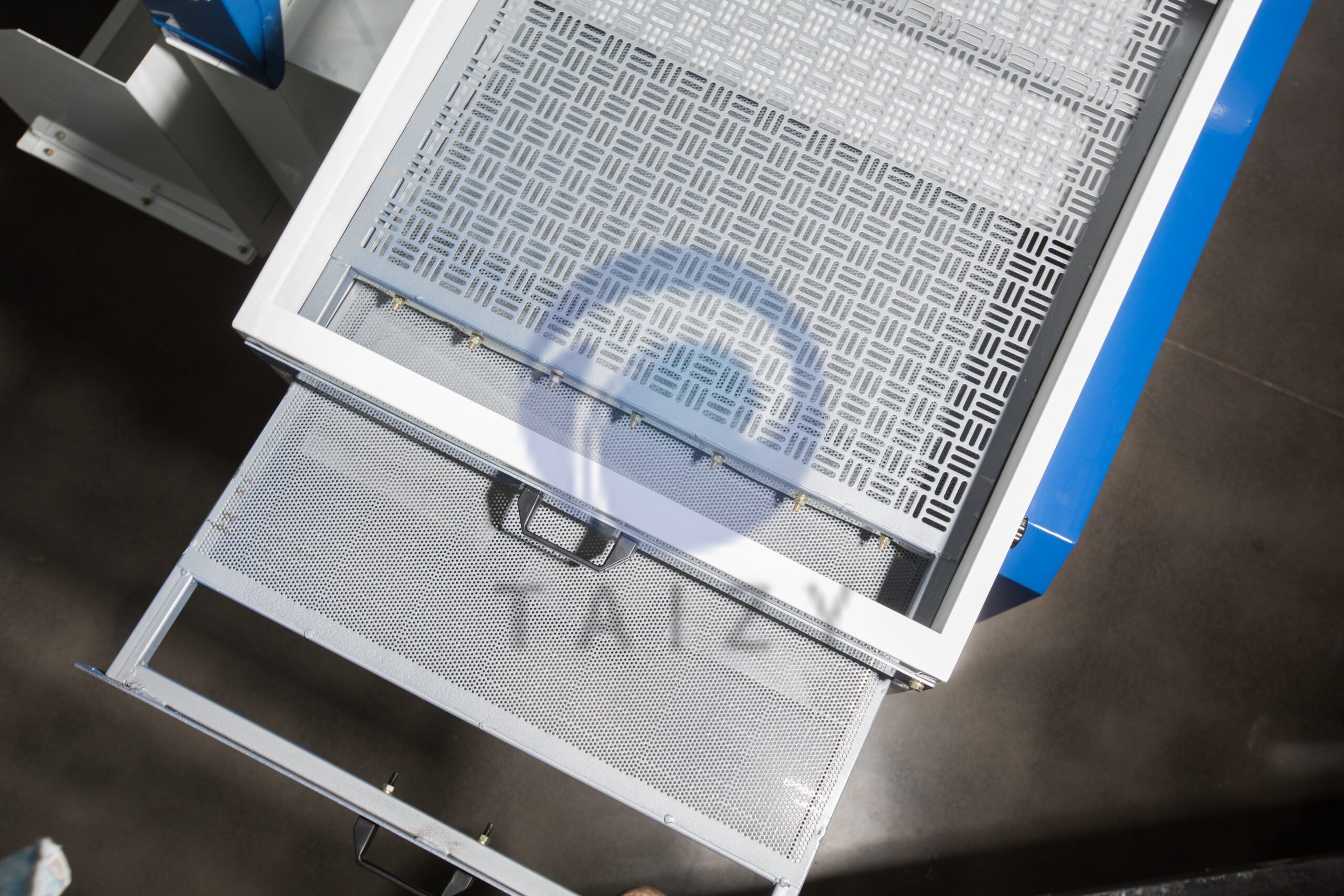

There are various types of rice cleaning equipment available, each with unique functions and advantages. Among them, the rice destoner is a commonly used impurity removal equipment, capable of effectively removing large particles such as stones and soil from rice, thereby improving the efficiency of subsequent processing and the quality of the finished rice.

Optimization of Process Flow:

By reasonably configuring and combining cleaning equipment, the cleaning process can be optimized to improve cleaning efficiency and the quality of the finished rice. Choosing appropriate cleaning methods and equipment combinations can maximize the removal of various impurities, ensuring the best cleaning effect.

Evaluation Indicators:

Key indicators for evaluating the effectiveness of cleaning equipment include the clean grain extraction rate and impurity removal rate. The clean grain extraction rate refers to the proportion of grains in the cleaned rice, while the impurity removal rate indicates the removal percentage of various impurities before and after cleaning.

These indicators help objectively measure the cleaning effect, allowing for timely adjustments to process parameters to improve production efficiency and product quality.

Conclusion

The rice cleaning process is a crucial step in ensuring the quality of the finished rice, with significant implications for the production efficiency and product quality of rice processing plants.

By selecting appropriate cleaning equipment and optimizing the process flow, various impurities in rice can be effectively removed, improving the purity and quality of the finished rice.

The recommendation to use a rice destoner as one of the cleaning equipment, with its efficient cleaning capability and reliable operational performance, will provide strong support for optimizing the rice cleaning process, achieving more efficient and higher-quality rice processing.